The service life of refractory fire bricks is not a fixed value. Its duration is influenced by a combination of material properties, operating conditions, and maintenance levels. Typically ranging from 1 to over 10 years, and even reaching 20 years in some special applications. To understand the reasons for this difference, we need to analyze both its inherent performance characteristics and the environmental conditions in which it is used.

1. Refractory fire brick materials

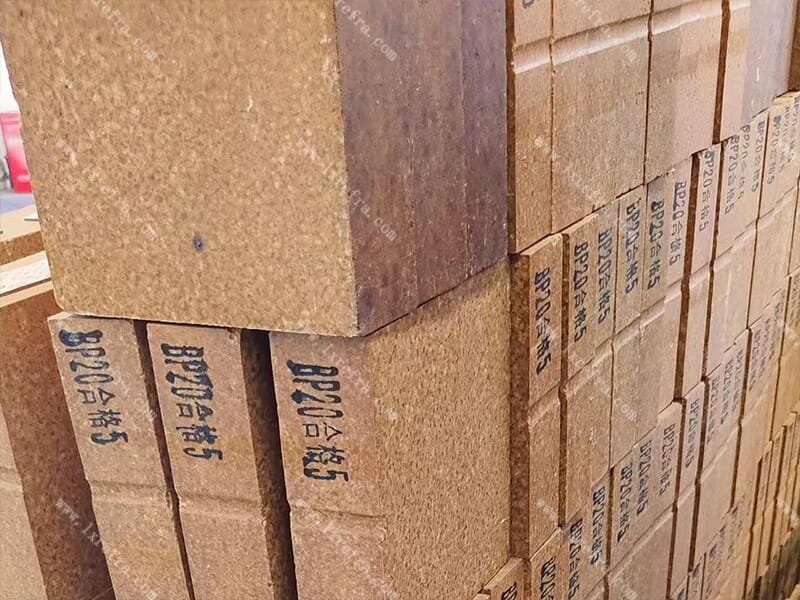

First, the material is the core foundation determining its service life. Refractory fire bricks can be classified according to their chemical composition into categories such as siliceous, clayey, high-alumina, and magnesia. Different materials exhibit significant differences in high-temperature resistance and corrosion resistance. For example, clay refractory bricks have a maximum service temperature of approximately 1500℃ and are mainly used in medium-temperature conditions such as hot blast stoves, with a service life of generally 3-5 years. Magnesia-carbon fire bricks, with their excellent slag resistance and high-temperature resistance (maximum service temperature exceeding 1800℃), have become the core material for blast furnace linings in steel production, and their service life can reach 8-12 years under stable operating conditions. In highly corrosive environments such as glass kilns, fused zirconia-corundum refractory bricks, due to their excellent resistance to molten glass erosion, can have a service life of 10-15 years.

2. Refractory fire brick usage environment

Secondly, the usage environment is a key variable affecting service life. Temperature fluctuations, media erosion, and mechanical wear are the three main factors leading to performance degradation. Frequent heating and cooling cycles cause thermal expansion and contraction of the bricks, resulting in cracks and shortening their service life. Alkaline clinker in cement kilns and corrosive gases in waste incinerators gradually erode the microstructure of the bricks. Material scouring and mechanical vibration within the furnace cause physical wear on the bricks. Taking waste incinerators as an example, due to the combined effects of corrosive flue gas and material erosion. The service life of refractory fire bricks is typically only 1-3 years, far shorter than that of bricks used in blast furnaces.

3. Installation process and maintenance measures

Finally, installation process and maintenance measures play a crucial role in extending the service life. Standardized masonry techniques (such as uniform mortar joints and staggered joints) can effectively reduce stress concentration in the bricks; regular inspections and repairs of localized damage, and proper control of furnace temperature fluctuations, can prevent localized deterioration from expanding into overall failure. Conversely, if the installation process is substandard or maintenance measures are lacking, even high-quality refractory fire bricks may fail in a short period.

In summary, the service life of refractory fire bricks is the result of the interaction between the material’s performance potential and actual usage conditions. There is no absolutely uniform standard; a comprehensive assessment based on the specific application scenario is necessary.