In order to test the slag resistance of refractory crucibles of different materials at high temperatures, to understand their corrosion resistance and permeability resistance during use, and to provide a reference for selecting matching refractory materials for smelting kilns. Our technical team conducted a static crucible slag resistance experiment on the slag from the waste circuit board incinerator. The following are the experimental principles and experimental steps of this experiment.

1.Principle of static crucible slag resistance test

The static crucible slag resistance test mainly involves adding test slag into crucibles of different materials, firing the crucibles in a high-temperature environment, cutting open the crucibles after cooling, and observing their cross-section to evaluate their erosion and penetration resistance.

The corrosion resistance of the crucible is closely related to its material. Generally speaking, crucibles made of high-grade refractory materials should have good resistance to erosion and permeability. Therefore, they can effectively prevent slag from invading the crucible at high temperatures or causing damage to the crucible.

2.Experimental Procedure

(1)Prepare crucible and experimental materials

Choose representative materials to make crucibles. This time, the products include direct bonded magnesia-chrome brick-20, fused bonded magnesia-chrome brick-20, zirconium composite corundum brick, special grade high alumina brick, first grade high alumina brick, chrome corundum brick D, and chrome slag brick.

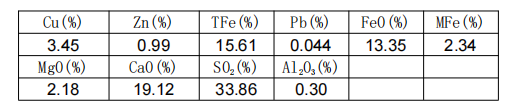

At the same time, prepare the corresponding high-temperature furnace and corrosive medium. The corrosive medium used in this experiment is the slag from the incinerator of waste circuit boards.

(2)Make a crucible

Use a drilling machine to drill holes with a diameter of 40 mm and a depth of about 40 mm on the selected sample bricks.

(3)Add ingredients

Add the well-mixed etching medium into each crucible so that the upper surface of the medium reaches approximately 2/3 of the total depth of each crucible.

(4)Place the crucibles

Place the crucibles in the high-temperature furnace in order. Adjust their positions to ensure that the crucibles are at a certain distance from the heating rods on both sides. The distance between the crucibles is uniform to avoid uneven heating of the crucibles.

(5)Start the high-temperature furnace

Set the heating rate and holding time, raise the high-temperature furnace to the specified temperature, and hold the temperature constant for a specified period of time.

(6)Heating and observation

First furnace experiment: Add 90g of corrosive medium and hold the test temperature at 1300°C for 6 hours. After holding, cool naturally to room temperature and observe the outer surface of the crucible and the medium.

Second furnace experiment: The seven materials from the first furnace were re-introduced with the corrosive medium, with 55g of corrosive medium added to each crucible. The test temperature was set at 1450°C and held constant for 6 hours. After holding, the crucibles were allowed to cool naturally to room temperature. The exterior surfaces of the crucibles and the medium were observed. The crucibles were cut open and dried, and the corrosion of the residue at the bottom of the crucibles and changes in the crucible surface were evaluated and recorded.

(7)Data collation

Summarize the experimental data. Analyze the ability of different refractory crucibles to resist slag erosion and penetration, and select the appropriate material.