In order to test the slag resistance of refractory crucibles of different materials at high temperatures, to understand their corrosion resistance and permeability resistance during use, and to provide a reference for selecting matching refractory materials for smelting kilns. Our technical team carefully designed and implemented a static crucible slag resistance test on the slag from the waste circuit board incinerator.

The following are the experimental results and conclusions of this experiment.

1.Experimental Results

After the first furnace test, the results showed that the corrosive medium did not penetrate into the crucible. Furthermore, the crucible remained intact, with no apparent corrosion or penetration.

The following figure shows the experimental results of two types of bricks. They are direct bonded magnesia chrome brick 20 and fused bonded magnesia chrome brick 20.

The results of crucibles of various materials after the second furnace experiment are as follows.

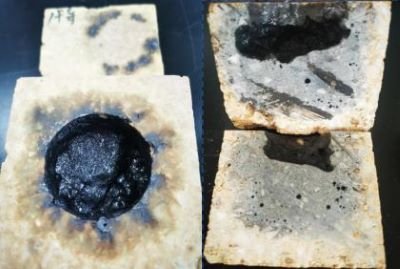

(1)First-grade high alumina bricks and special-grade high alumina bricks

The cross-sections of the first-grade high-alumina brick and the special-grade high-alumina brick after testing and cutting show that the corrosive medium of the former has completely penetrated into the interior of the brick, while the corrosive medium of the latter has mostly penetrated into the interior of the brick.

At the same time, both materials have cavitation phenomena on the bricks at this temperature.

Therefore, the ability of these two materials to resist this corrosive medium is relatively poor.

(2)Zirconium corundum composite bricks

The cross-section of the zirconium-corundum composite brick after testing and cutting shows that the corrosive medium partially penetrates into the interior of the brick, and obvious penetration can be seen. However, a clear slag column is left. Therefore, the material has good anti-corrosion and anti-penetration properties.

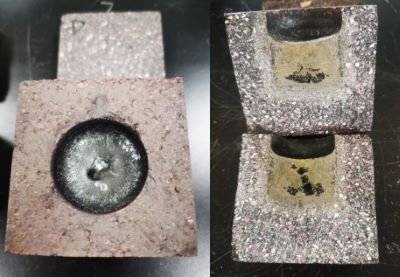

(3)Direct bonded magnesia chrome bricks 20 and fused bonded magnesia chrome bricks 20

The cross-sections of direct-bonded magnesia-chrome bricks 20 and fused-bonded magnesia-chrome bricks 20 after testing and cutting show that both have obvious penetration on the surface and no cracks.

The former showed no obvious erosion on the cut cross-section. The latter showed obvious cracks on the cross-section, but no obvious erosion. At the same time, both bricks had no obvious column slag, and most of the corrosive medium had penetrated into the crucible.

Therefore, both bricks had relatively good resistance to erosion by the medium, but poor resistance to penetration.

(4)Chrome slag bricks and chrome corundum bricks D

The cross-section of the chrome slag brick after the test and after the cut shows that the surface medium overflows, there is obvious penetration, and there are no cracks. The cross-section after the cut shows obvious cracks, but no obvious erosion. There are small slag pillars, and the erosion medium partially penetrates into the crucible.

The cross-section of the chrome corundum brick D after the test and after the cut shows no obvious penetration and no cracks. The cross-section after the cut shows no cracks and no obvious erosion. There are obvious slag pillars, and the erosion medium partially penetrates into the crucible.

Therefore, the chrome slag brick and the chrome corundum brick have relatively good resistance to erosion and penetration of this medium.

2. Conclusion of static crucible slag resistance test

The smelting raw materials used in this static crucible caused varying degrees of corrosion and penetration into all seven brick materials. The penetration and corrosion patterns within the crucibles reveal the following.

(1)There is basically no corrosion at the contact points between chrome corundum D, chrome slag bricks, Dian-20, Zhi-20, and zirconium corundum composite bricks and the raw materials.

(2)The corrosion medium infiltrated more into the Dian-20 and Zhi-20 bricks, and micro cracks appeared on the Dian-20 during the second furnace test.

(3)The first-grade high-alumina bricks and special-grade high-alumina bricks have obvious corrosion.

Therefore, the order of performance of these seven products in terms of resistance to corrosion from smelting raw materials is: chrome corundum brick > chrome slag brick > zirconium corundum composite brick ≈ fused-bonded magnesia-chrome-20 ≈ directly bonded magnesia-chrome-20 > premium high-alumina brick ≈ first-grade high-alumina brick.

The above results show that chrome corundum bricks have obvious anti-erosion and penetration effects. Therefore, it is recommended to choose chrome corundum products.