In high-temperature industrial settings, refractory bricks are indispensable core materials.

From boiler operation to kiln smelting, from incineration to high-temperature reactors, the quality of refractory bricks directly determines equipment lifespan and production safety.

Many companies struggle with the choice: which refractory brick is more durable and adaptable?

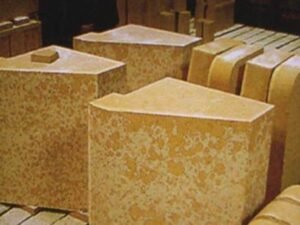

There are various types of commonly used refractory bricks, among which high-alumina refractory bricks have become the mainstream choice due to their superior performance.

They use high-alumina bauxite as the main raw material, with an alumina content of over 48%, and can withstand temperatures up to 1750-1790℃, resisting acid and alkali corrosion and mechanical wear at high temperatures.

Whether in blast furnaces of steel plants, rotary kilns of cement plants, or critical components of glass kilns. High-alumina refractory bricks perform reliably and are among the longest-lasting refractory bricks in industrial applications.

Clay refractory bricks represent another widely used type. They feature low raw material costs, mature processing technology, and high temperature resistance of approximately 1580-1770℃.

It is suitable for medium- and low-temperature industrial applications, such as ordinary boilers, heating furnaces, and flues. It offers high cost-effectiveness and convenient replacement and maintenance, making it popular among small and medium-sized enterprises. However, its service life is slightly shorter than high-alumina refractory bricks in ultra-high temperature or highly corrosive environments.

Silica refractory bricks, with silica as their main component, exhibit outstanding high-temperature resistance. Withstanding temperatures of 1690-1750℃, and possess good thermal stability. People commonly use them for the walls and tops of glass kilns and acidic furnace linings in the metallurgical industry. However, alkaline environments easily damage them, which limits their application to specific scenarios.

Magnesium refractory bricks are alkaline refractory bricks, withstanding temperatures up to 1800℃ and exhibiting strong resistance to alkaline slag erosion. They are mainly used in steelmaking converters and non-ferrous metal smelting kilns.

However, their thermal shock resistance is poor, making them prone to cracking in environments with drastic temperature changes. Therefore, they require the use of appropriate insulation structures.

When selecting refractory bricks, you must conduct a comprehensive assessment considering the operating temperature, the environmental medium, and the equipment requirements.

High-alumina refractory bricks are the long-term choice for most companies due to their wide applicability and durability. Clay refractory bricks are suitable for budget-constrained, low-to-medium temperature applications. While silica and magnesia refractory bricks offer advantages for specific working conditions.

High-quality refractory bricks can reduce equipment maintenance frequency and lower production costs. If you are still struggling to choose which type of refractory brick to use, or if you are looking for products that are suitable for your specific working conditions and have a longer service life, please contact us!

We provide professional refractory brick selection advice and supply a variety of high-alumina, clay, silica, and magnesia refractory bricks, ensuring product quality and performance throughout the entire process. We look forward to working with you to solve refractory challenges in high-temperature environments!