Common refractory materials used in heat treatment furnaces include refractory clay bricks, high-alumina bricks, anti-carburization bricks, refractory concrete, silicon carbide products, various refractory fibers, and refractory coatings. Refractory clay bricks are the most commonly used in heat treatment furnaces.

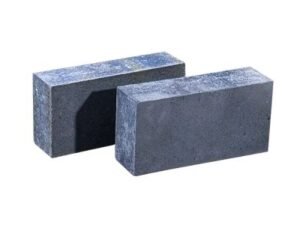

1. Refractory Clay Bricks

Refractory clay bricks are primarily made from refractory clay and kaolin. The chemical composition of refractory clay bricks is Al₂O₃ (30%-40% by mass), SiO₂ (50%-65% by mass), and the remainder is various metal oxides. Ordinary clay bricks are weakly acidic, with a softening point under load of 1350°C.

They have a low coefficient of expansion, thermal conductivity, and specific heat capacity, and exhibit good thermal vibration stability. Their maximum operating temperature is 1300-1400°C.

Ordinary clay bricks are the most commonly used in heat treatment furnaces, generally used for building the furnace roof, furnace floor, furnace walls, and combustion chamber.

In the heat treatment furnace, a chemical reaction will occur between the iron-chromium-aluminum alloy and the clay brick, and the clay brick will corrode and damage the iron-chromium-aluminum alloy. Clay bricks are easily damaged by the erosion of CO and H2 in a controlled atmosphere.

2. High-alumina bricks

The mass fraction of Al2O3 in high-alumina bricks is greater than 48%, and the rest is mainly SiO2, with very few impurities. Ordinary high-alumina bricks are divided into three grades according to the mass fraction of Al2O3, namely, the mass fraction of Al2O3 is greater than 48%, the mass fraction of Al2O3 is greater than 55%, and the mass fraction of Al2O3 is greater than 65%.

High-alumina bricks have the advantages of high refractoriness, good high-temperature structural strength and good chemical stability, but they are expensive and are mostly used in high-temperature heat treatment furnaces and resistance wire or resistance belt shelf bricks, thermocouple tubes, muffle furnace cores, etc.

3. Anti-carburization bricks

In a reducing atmosphere containing CO and H2, Fe2O3 in refractory clay bricks or refractory high-alumina bricks will react with the atmosphere to generate metallic iron. Iron acts as a catalyst, accelerating the decomposition of CO, releasing carbon black that is deposited within the bricks. The formation of iron and its subsequent conversion to Fe₃C loosens the brickwork. Furthermore, the deposition of carbon black within the brickwork causes the bricks to expand in volume. This can lead to premature failure of furnace linings in conventional refractory clay bricks or high-alumina refractory bricks. Therefore, the Fe₂O₃ content in anti-carburization bricks must be below 1%.

4. Silicon Carbide Refractory Products

Silicon carbide refractory products are primarily composed of SiC. They offer high refractoriness and high-temperature structural strength, as well as excellent wear resistance, thermal shock stability, and thermal and electrical conductivity. Depending on the manufacturing process, they can be used for heating elements and floor plates in high-temperature furnaces. Silicon carbide products are susceptible to oxidation at temperatures above 1300°C and are easily corroded by alkaline slag.