In high-temperature industrial scenarios such as steelmaking, cement, and glassmaking, the choice of refractory materials directly affects equipment life and production safety. Different scenarios require different refractory materials due to differences in temperature, medium, and mechanical effects. The following are targeted selection suggestions to help you avoid selection errors.

1.Steelmaking converter/electric furnace: slag-resistant and wear-resistant refractory materials are preferred

Steelmaking processes often reach temperatures of 1600-1800°C, and are subject to erosion by molten steel and acidic/alkaline slag. Magnesia-carbon bricks are the preferred choice.

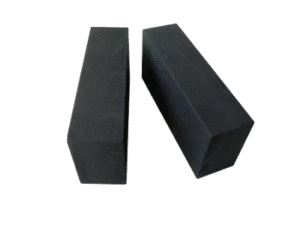

Containing high-purity magnesia and graphite, they offer both high-temperature resistance (over 2000°C) and resistance to slag erosion. Optimized formulations with antioxidants such as Al and Si can extend the life of converter linings to over 1200 heats. Magnesia-chrome bricks can be used in refining furnaces, offering enhanced thermal shock resistance. Quality should be assessed based on raw material purity (e.g., MgO ≥ 95%, Cr₂O₃ ≥ 20%) and production processes (e.g., isostatic pressing and precise temperature-controlled firing).

2. Cement Rotary Kilns: Emphasize Alkali Resistance and High-Temperature Fluctuation Resistance

Cement kilns operate at temperatures of approximately 1450-1600°C in the calcining zone, where alkali metals (K₂O, Na₂O) corrode. High-slag-resistant magnesia bricks are highly suitable. These bricks optimize the core parameters of bulk density (≥3.0g/cm³) and apparent porosity (≤16%) to reduce alkali vapor penetration and prevent spalling. Given the large temperature fluctuations in the transition zone, spinel magnesia bricks are recommended. They offer excellent thermal shock resistance, can withstand frequent temperature increases and decreases, and reduce the risk of cracking.

3. Glass Kilns: Emphasize Corrosion Resistance and Structural Stability

Glass kilns operate at melt temperatures of 1500-1600°C and are subject to erosion by molten glass and flames. Fused magnesia-alumina spinel bricks are the key choice. Their dense crystal structure significantly resists molten glass corrosion, making them far superior to ordinary magnesia bricks, making them particularly suitable for the melt pool bottom and walls. The kiln roof is subject to high-temperature radiation and can be used with high-alumina bricks.

The Al₂O₃ content must be controlled at ≥75% to ensure deformation resistance under long-term high-temperature conditions.

4.Core Selection Principles: Matching the Scenario + Focusing on Key Indicators

Regardless of the high-temperature scenario, selection must follow the principle of “scenario requirements → material properties → parameter verification.” First, determine the temperature range, corrosive media, and mechanical effects; then consider the material’s high-temperature resistance, corrosion resistance, and thermal shock stability. Finally, verify compatibility with actual application cases using key parameters (such as MgO content, bulk density, and apparent porosity) to select the most cost-effective refractory material.