Reverberatory furnace and blast furnace are two key pieces of equipment commonly found in industrial smelting. While similar in appearance, they are fundamentally different systems internally. Understanding their differences can help you better match refractory materials and improve equipment efficiency.

1.Differences in structural design and working principles

(1)Different structural designs

First, the blast furnace adopts a vertical structure. The overall shape is a towering cylinder, and from top to bottom it is mainly composed of the furnace throat, furnace body, furnace waist, furnace belly and furnace hearth.

In contrast, reverberatory furnaces are mostly horizontal structures. The furnace body is rectangular or round, and is mainly composed of a furnace top, furnace walls, furnace bottom and combustion chamber.

(2)Different working principles

The blast furnace is centered around a continuous reduction reaction. The raw materials are loaded from the top and hot air is blown in from the bottom. The combustion of coke produces high-temperature reducing gas, which reduces the iron ore into molten iron, which is eventually discharged from the furnace.

Secondly, the airflow and material in the blast furnace move in the opposite direction, the heat exchange efficiency is high, and it is suitable for large-scale continuous production.

Reverberatory furnaces are different. This method indirectly heats the materials within the furnace by reflecting flames or high-temperature flue gases off the furnace roof. The materials do not directly contact the fuel. Therefore, it focuses more on smelting or refining processes. For example, it can be used for the rough smelting or tempering of non-ferrous metals such as copper and lead.

2.Reverberatory furnace: unique heat transfer and application scenarios

Specifically, the core feature of the reverberatory furnace is “reflective heating”.

After the fuel burns in the combustion chamber, the high-temperature flue gas flows along the top of the furnace and transfers heat to the material at the bottom of the furnace through radiation, causing the material to gradually melt or complete a chemical reaction.

In addition, the heating method of the reverberatory furnace determines that its temperature distribution is relatively uniform, but its thermal efficiency is lower than that of the blast furnace. Therefore, auxiliary equipment is usually required to improve energy utilization.

Therefore, reverberatory furnaces are more suitable for processing materials with lower melting points and requiring precise temperature control. Examples include the smelting of non-ferrous metal concentrates, the remelting of scrap metal for recycling, or the heating of steel in the steel industry.

Its production mode is mostly intermittent or semi-continuous, with high flexibility, but the processing capacity of a single furnace is usually smaller than that of a blast furnace.

3.Core considerations for refractory material selection

Accordingly, the differences in operating conditions between the two furnace types place different requirements on refractory materials.

(1)Refractory materials for blast furnaces

The temperature and chemical environment in different parts of the blast furnace are complex.

First, the upper portion of the furnace shaft. Here, temperatures are lower, requiring clay bricks or high-alumina bricks that are resistant to wear and alkali metal corrosion.

Second, the area from the hearth to the furnace hearth. Here, temperatures exceed 1500°C and are subject to erosion by molten iron and slag. Therefore, carbon bricks, corundum bricks, or silicon carbide bricks are required to ensure high strength and slag resistance.

For this reason, refractory materials for blast furnaces must balance high-temperature resistance, corrosion resistance, and thermal shock stability.

(2)Refractory materials for reverberatory furnaces

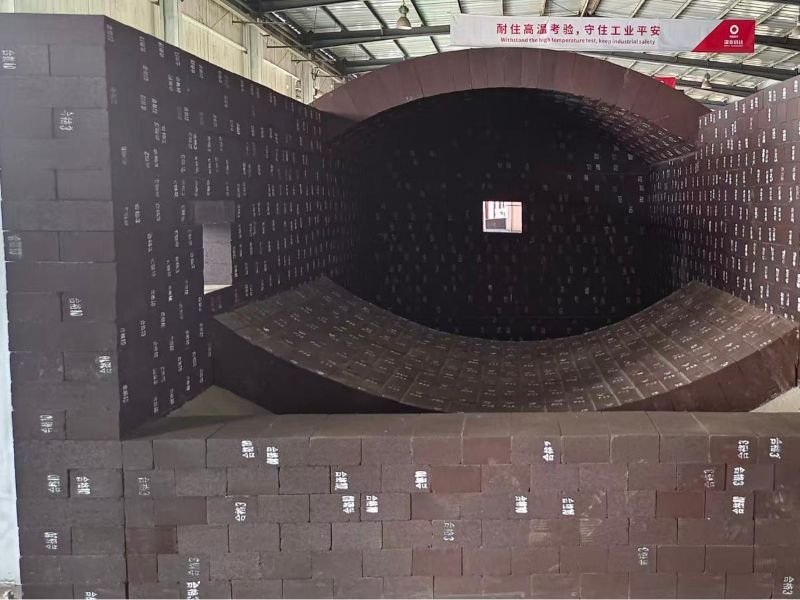

Reverberatory furnaces are subjected to long-term erosion by high-temperature flue gas and erosion by molten slag. Therefore, magnesia-chrome bricks and high-alumina bricks with good thermal shock resistance should be used for their roof and walls.

The furnace bottom needs magnesia bricks or zirconium bricks that are resistant to molten metal penetration.

In addition, the intermittent operation characteristics of the reverberatory furnace require the refractory material to withstand frequent temperature fluctuations to avoid cracking and spalling.

In short, whether it’s a reverberatory furnace or a blast furnace, the brick shape, quality, and layers must be aligned with the process parameters. Finding a suitable refractory brick supplier can save you more downtime than simply comparing prices.