Converter refractory bricks for saleThe key to turning molten iron into molten steel lies in a furnace that can “rotate”. So, what kind of furnace is a converter? This article will introduce you to the true face of the converter from the following points.

1.The main body and function of the converter

A converter, as the name suggests, is a rotating smelting furnace.

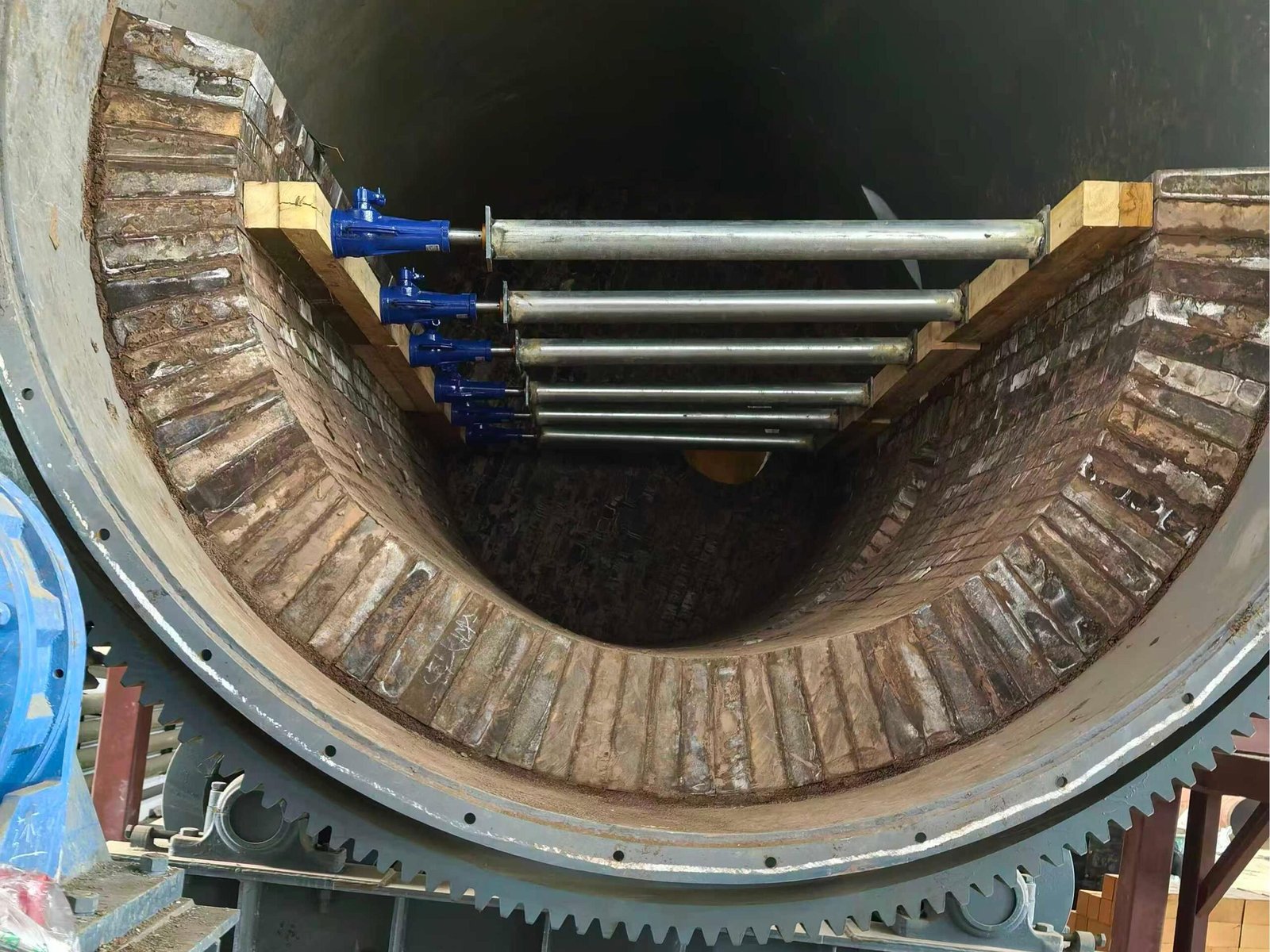

(1)Converter body

Specifically, it is a cylindrical reactor used in steelmaking. The main body consists of a sturdy steel shell.

The steel plates are welded into a pear-shaped container, with a ring of gears fixed in the center.

The ear shafts on both sides are mounted on the bearing seats, and the motor drives the gear ring through the reducer, allowing the furnace body to stop arbitrarily between 0°–360°.

The furnace mouth is at the front and top, and molten iron, scrap steel and slag-making agents all enter from here.

There are several tuyere at the bottom of the furnace, and oxygen is injected at high speed through a spray gun or bottom blowing element.

(2)Function

The main function of the converter is to convert liquid pig iron from the blast furnace into steel.

Pig iron has a high carbon content and contains impurities such as silicon, manganese, and phosphorus. Therefore, its properties are brittle and hard, and its uses are limited. The core task of the converter is to induce a violent oxidation reaction by blowing high-purity oxygen into the high-temperature molten iron.

In this process, excess carbon and other impurity elements are rapidly oxidized and removed, thereby adjusting the chemical composition of the molten iron to meet the standards of steel.

Therefore, the converter is one of the main equipment for achieving large-scale and high-efficiency steelmaking.

2.Harsh working environment

The internal working environment of the converter is extremely harsh.

When the oxygen stream hits the molten iron at high speed, the temperature inside the furnace will quickly rise to over 1600 degrees Celsius.

At the same time, elements like carbon, silicon, and manganese react with oxygen in an exothermic reaction. This not only releases a large amount of heat, maintaining the high temperature within the furnace, but also forms a complex slag.

Furthermore, the entire smelting process causes continuous physical erosion and chemical attack on the furnace lining.

This demanding operating condition places extremely stringent demands on the performance of the furnace lining material.

3.Refractory lining: What bricks are used for converter lining?

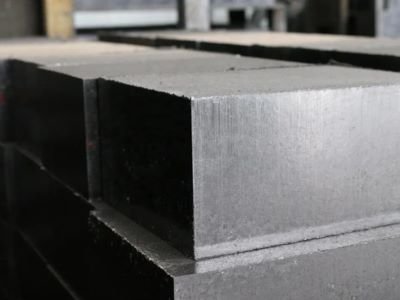

The transition begins with temperature. Peak temperatures in the converter reaction zone can reach 1700°C, with FeO content in the slag as high as 20%. Combined with the high-speed airflow, ordinary clay bricks cannot withstand this. Therefore, high-purity magnesia-carbon bricks are commonly used for the working layer.

Magnesia carbon bricks have a high melting point, excellent resistance to slag erosion, and good thermal shock stability. Therefore, they can effectively resist the chemical corrosion of slag and withstand the huge temperature changes during charging and tapping.

Behind the working lining of magnesia carbon bricks, a permanent lining is usually set. Magnesia calcium bricks or a second layer of magnesia carbon bricks are generally used here to take into account both thermal insulation and safety.

A well-designed, high-quality refractory lining is the cornerstone of stable converter operation.

As you can see from this, the secret to efficient converter steelmaking lies in both converter performance and refractory performance. Therefore, it’s crucial to partner with an experienced and technically reliable refractory supplier and select the right refractory material with excellent performance.