In the field of non-ferrous metal smelting industry, various types of kilns are widely used, they play an indispensable role according to the characteristics of different non-ferrous metals and smelting process requirements.

1. Reverberatory furnace

Reflex furnace is a kind of large thermal equipment commonly used in non-ferrous metal smelting. Its structure is characterized by a wide furnace body. After burning in the combustion chamber, the flame crosses the fire bridge into the melting chamber, and the heat is transferred to the charge for melting through the reflection of the furnace top and furnace wall.

It is widely used in copper smelting and can handle a variety of copper concentrates and secondary copper resources. Its advantage is that it can adapt to different raw material composition and particle size, strong adaptability to raw materials, large-scale continuous production, and large production capacity.

However, the thermal efficiency of the reflector furnace is relatively low, the fuel consumption is high, and it faces certain challenges in environmental protection, such as large smoke volume, low sulfur dioxide concentration, and high subsequent flue gas treatment cost.

2. Blast furnace

Blast furnace is mainly used in the smelting of heavy metals such as lead and zinc. It is a vertical cylindrical or rectangular furnace body, the furnace body is provided with a tuyere, through the furnace drum air or oxygen-rich air, so that coke and other fuels burning high temperature, so as to melt the charge.

In the process of lead smelting, lead concentrate, coke, flux, etc. are added from the top of the furnace, and under the high temperature and strong reducing atmosphere in the furnace, lead and other valuable metals are reduced and melted, forming lead liquid and slag layers, which are released from different outlets at the bottom of the furnace.

The advantage of blast furnace is that it has good adaptability to raw materials, can handle complex composition of ore, and can realize the recovery of a variety of metals at the same time.

However, the blast furnace has some problems, such as high energy consumption, low sulfur dioxide concentration in flue gas, which is not conducive to acid production, and the equipment is relatively complex and the investment is large.

3. Flash furnace

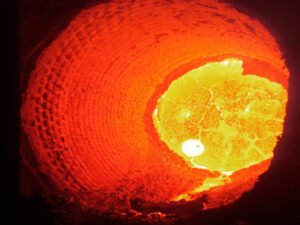

Flash furnace plays an important role in the smelting of non-ferrous metals such as copper and nickel. The principle is that the dried and finely ground fine ore powder is mixed with air or oxygen-rich air and sprayed into the reaction tower of the flash furnace at high speed, and the fine ore powder is heated and oxidized in an instant.

The obvious advantages of flash furnace are high melting strength, large production capacity, relatively low energy consumption, and can produce high concentration of sulfur dioxide flue gas, which is convenient for subsequent acid production, and is conducive to environmental protection and comprehensive utilization of resources.

However, the flash furnace has strict requirements on the particle size and moisture of raw materials, and needs to be equipped with a special raw material drying and grinding system, and the equipment investment and operation management requirements are higher.

4. Rotary kiln

Rotary kiln has various uses in non-ferrous metal smelting, and can be used in alumina production clinker sintering, zinc roasting and other processes. It is an inclined and slowly rotating cylindrical equipment, the material enters the kiln from the end, with the rotation of the kiln body, the material continuously rolls in the kiln and moves towards the kiln head, in the process of moving with the hot gas flow for heat exchange, to complete a series of physical and chemical changes such as drying, roasting, sintering.

The advantages of rotary kiln are strong adaptability to materials, can handle materials of different shapes and properties, continuous and stable production process, and can achieve large-scale production. However, the thermal efficiency of rotary kiln is limited, the floor area is large, and the rotation and temperature control of the kiln body need to be precisely managed during operation to ensure the smooth progress of production and the stability of product quality.

These commonly used kilns in the non-ferrous metal smelting industry, each with its own unique process characteristics and scope of application, play a key role in the extraction and refining process of non-ferrous metals, and with the continuous progress of technology, they are also continuously optimized and innovative to adapt to the increasingly stringent environmental requirements and the development trend of efficient use of resources.