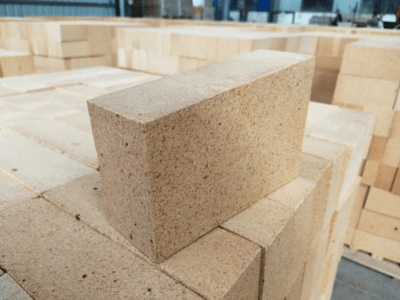

Furnace bricks are essential refractory materials in industrial furnaces, used to withstand high temperatures, mechanical stress, and chemical erosion. Based on raw materials, alumina content, and performance characteristics, furnace bricks used in industrial furnaces can be classified into the following main types.

1. Refractory clay bricks

Refractory clay bricks are typically made from natural refractory clay and contain a suitable amount of alumina (Al₂O₃).

Specifically, clay bricks have the following main characteristics:

① Stable performance at medium and high temperatures;

② Good thermal shock resistance;

③ An economical and efficient solution suitable for general furnace and kiln applications.

Clay bricks are widely used in reheating furnaces, heat treatment furnaces, and auxiliary furnace areas.

2. High-alumina furnace bricks

High-alumina bricks are designed for higher temperatures and harsher industrial furnace environments. Due to their higher alumina content, these fire bricks have higher refractoriness, strength, and resistance to slag erosion and chemical corrosion.

Specifically, high-alumina bricks have the following main advantages:

① Higher fire resistance under load;

② Higher mechanical strength;

③ Longer service life in high-temperature zones.

High-alumina bricks are commonly used in steelmaking furnaces, cement kilns, glass furnaces, and other industrial furnaces exposed to high-temperature and heavy-load environments.

3. Insulating bricks

Insulating bricks are lightweight refractory bricks primarily used for thermal insulation in industrial furnaces. Typical characteristics include:

① Lightweight structure;

② Excellent thermal insulation performance;

③ Improve energy efficiency.

Insulating bricks are typically used as backings or in non-load-bearing areas of industrial furnaces, rather than directly in high-temperature areas.

4. Special fire bricks

For specific industrial furnace conditions, special refractory bricks may be required. These special refractory bricks include acid-resistant bricks, alkali-resistant bricks, or bricks with shapes

customized for specific furnace zones.

This type of furnace brick is suitable for the following situations:

① Severe chemical corrosion;

② Frequent thermal shocks;

③ Involves a special furnace structure.

Customized furnace bricks help optimize furnace lining performance and extend furnace life under harsh operating conditions.

5. Selection of fire bricks for industrial furnaces

The selection of suitable refractory bricks depends on a variety of factors, including operating temperature, furnace atmosphere, mechanical load, and chemical corrosion.

Different types of refractory bricks can be used in combination in the same furnace lining system to achieve optimal performance and cost-effectiveness.

Henan Ruitai Lianxin Refractory Materials Co., Ltd. has 20 years of experience in refractory material production. It can not only provide customers with high-quality refractory bricks that meet the required standards, but also provide the most suitable kiln operating conditions solutions. Please feel free to contact us if you have any needs.

Choosing Ruitai Lianxin means choosing strength.