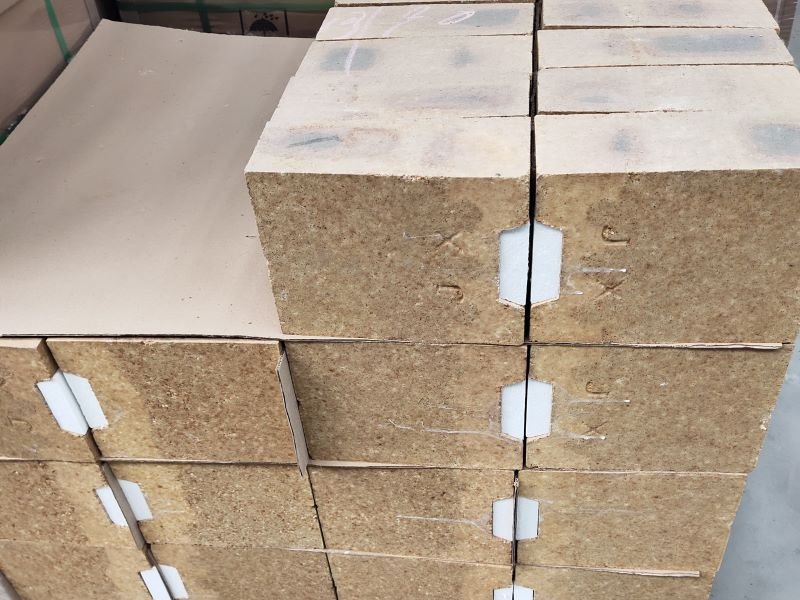

In high-temperature industrial environments like steelmaking, cement production, and waste incineration, refractory materials face three major threats: thermal shock, corrosion, and wear.Traditional refractories often fail rapidly under these multiple impacts, but phosphate bricks, with their unique “three-proof” capabilities, have become a key solution to these harsh industrial challenges.

Challenge 1: Thermal Shock—From “Brittle Fracture” to “Flexible Buffering”

When the kiln temperature drops suddenly from 1500°C to 800°C in a matter of minutes, traditional refractory bricks generate internal stress due to differences in thermal expansion coefficients, leading to cracking and spalling.

However, the solution for phosphate bricks lies in their microstructural design. Their phosphate binder forms a nanoscale network at high temperatures, acting like countless “micro-springs” to absorb thermal stress.

Experimental data shows that in a 1100°C water-cooling cycle test, ordinary high-alumina bricks can withstand only five cycles before breaking. Phosphate bricks, on the other hand, can withstand over 30 thermal shock cycles, extending their lifespan by six times.

Challenge 2: Corrosion—Chemical Slag’s “Insulator”

Alkaline oxides (such as CaO and FeO) in steel slag and sulfur and chlorine compounds in cement kilns act like strong acids, corroding traditional bricks.

The core defense of phosphate bricks lies in their chemical inertness: their main component, aluminum phosphate (AlPO₄), forms a dense ceramic phase at high temperatures. Upon contact with molten slag, a highly viscous glass protective layer forms on the surface, preventing molten slag from penetrating.

In the acidic gas environment of a waste incinerator, the corrosion rate of phosphate bricks is only one-eighth that of clay bricks, with annual wear less than 3mm.

Challenge 3: Wear—A Hard Shield Against Mechanical Impact

In areas like rotary kilns and material conveyor channels, high-temperature materials continuously erode the brick surface.

Phosphate bricks address this challenge through a dual strengthening mechanism: the aggregate is made of high-hardness corundum (Mohs hardness 9.0), and the binder forms a ceramic “bonding bridge,” imparting both toughness and wear resistance to the overall structure.

Three-in-One Protection: The “All-Round Guardian” of Industrial Kilns

The true advantage of phosphate bricks lies in their simultaneous solution to three major pain points.

In the cement kiln transition zone, they must withstand temperatures of 1500°C (thermal shock) at the flame end, corrosion from the clinker melt (chemical attack), and wear from rolling materials (mechanical impact).

At the top of the electric arc furnace, they face the dual challenges of arc thermal shock and molten steel splash.

Through customized formulations (such as the addition of zircon for toughening and silicon carbide for wear resistance), phosphate bricks can be precisely tailored to the needs of different scenarios, achieving “one brick for multiple functions.”

When thermal shock, corrosion, and wear are no longer the “ceilings” of kiln life, companies will benefit from longer production cycles, lower O&M costs, and the potential for more sustainable development—the core value of phosphate bricks in meeting the most demanding challenges.