The internal operating environment of a cement kiln is extremely harsh, therefore, choosing the right lining material is crucial. High-quality refractory fire bricks are key to ensuring the long-term stable operation of kilns. Its application in cement kilns is mainly reflected in the following five aspects.

1. Resist extreme high temperatures and ensure equipment safety

First of all, the most basic advantage of refractory fire bricks lies in their excellent high-temperature resistance.

The temperature inside a cement kiln can reach over 1400℃, and high-quality refractory fire bricks can form a strong heat insulation barrier.

This effectively protects the kiln’s steel structure from burn damage, thus ensuring the safety of the entire production equipment.

2. Resist chemical erosion and maintain kiln stability

The materials and gases used in the cement production process are highly alkaline and have a severe chemical corrosive effect on the lining.

Therefore, choosing the right refractory bricks is crucial.

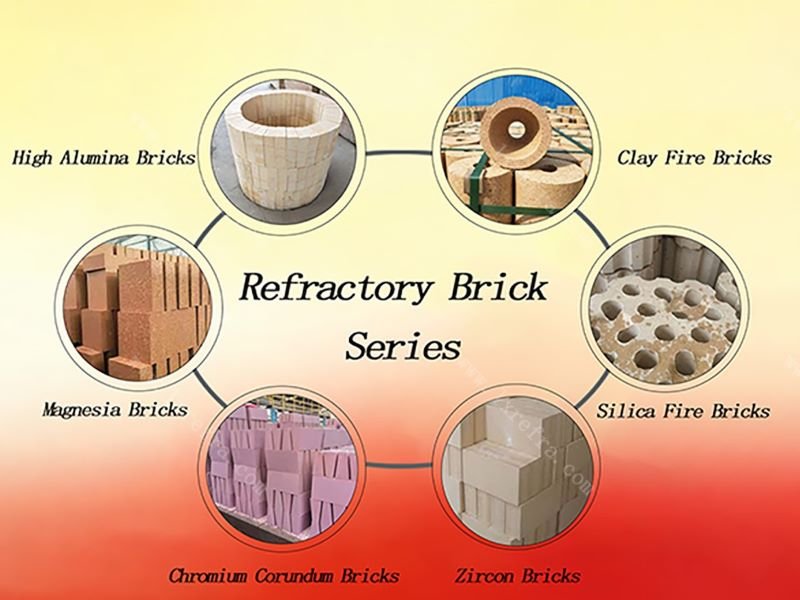

For example, magnesia-chrome refractory fire bricks or magnesia-iron spinel bricks are often used in the firing zone, while high-alumina bricks or anti-spassing high-alumina bricks are mostly used in the transition zone.

These special refractory fire bricks, with their unique chemical composition, can effectively resist the erosion of clinker and alkaline vapors, thereby maintaining the integrity and stability of the kiln space.

3. Withstands mechanical wear and tear, extending service life

Meanwhile, when the cement kiln is rotating, the kiln lining will be continuously eroded and worn by the material.

Of course, high-quality refractory fire bricks have high mechanical strength and good wear resistance. A robust brick structure ensures the kiln remains stable during long-term operation, reducing unplanned downtime caused by brick spalling or breakage, thereby extending the overall service life of the kiln lining.

4. Improve thermal efficiency and reduce energy consumption

The excellent heat insulation properties of refractory bricks can reduce heat loss from the surface of the kiln.

This not only reduces fuel consumption and saves production costs, but also fully aligns with the modern industrial trend of green and energy-saving development.

5. Optimize overall costs to reflect the economic value of refractory bricks

Although high-quality refractory bricks may be relatively expensive, their long service life and low maintenance frequency make the overall cost lower.

Therefore, partnering with professional refractory brick manufacturers and purchasing reliable products is a wise investment.

Henan Ruitai Lianxin Refractory Materials Co., Ltd. has 20 years of experience in refractory material production. It can not only provide customers with high-quality refractory bricks that meet the required standards, but also provide the most suitable kiln operating conditions solutions.

Please feel free to contact us if you have any needs. Choosing Ruitai Lianxin means choosing strength.