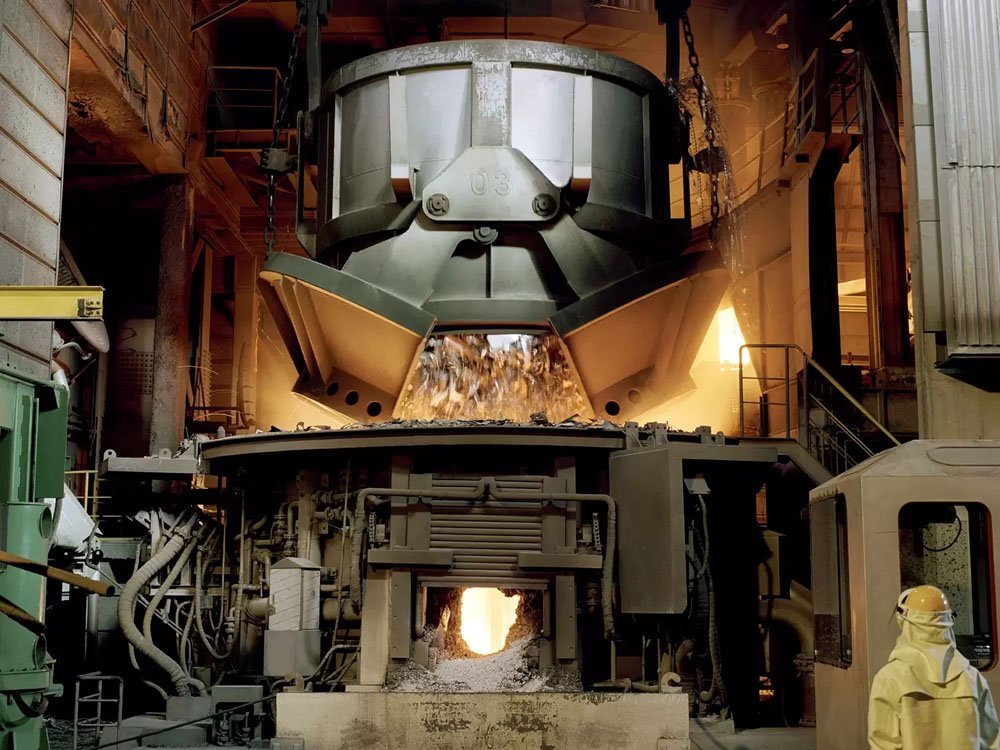

In steel smelting, the durability of kilns directly depends on the lining material. Refractory fire bricks are the basic unit that makes up the kiln lining under these extreme working conditions, and their performance directly affects production efficiency and safety.

1. Types and core properties of refractory bricks

According to chemical properties, refractory fire bricks are mainly classified into three categories: acidic, alkaline, and neutral.

High-alumina refractory bricks, silica bricks, and magnesia-carbon refractory bricks are commonly used in the steel industry.

High-quality refractory bricks must possess resistance to slag erosion, high-temperature compressive strength, and thermal shock stability. Therefore, the purity of the raw materials and the sintering process directly determine its service life.

In addition, different smelting stages have different requirements for the thermal conductivity and wear resistance of refractory bricks. Therefore, the selection of equipment must be matched with the specific working conditions.

High-quality refractory brick manufacturers typically offer different grades of products based on the specific operating conditions of the kiln used by the customer, such as the blast furnace, converter, or electric furnace.

2. Kiln lining configuration and economic considerations

The refractory bricks selected for kilns vary depending on their operating conditions.

For example, blast furnace hearths often use a combination of carbon composite bricks and corundum bricks, while converter working layers generally use magnesia-carbon bricks to resist the erosion of molten steel.

Because the operating temperature of continuous casting tundishes is relatively low, lightweight aluminosilicate insulating bricks are commonly used.

Of course, the price of refractory bricks is affected by the cost of raw materials, manufacturing costs and logistics costs. Therefore, when purchasing, one should not only look at the unit price, but also assess the overall life cycle cost of the brick lining.

Meanwhile, market supply and demand, as well as batch size, will also cause fluctuations in the final price. Therefore, long-term cooperation usually leads to more stable supply conditions.

3. How to choose a suitable refractory brick supplier

A high-quality refractory brick supplier should not only provide products, but also have the ability to design kiln linings and provide construction guidance services.

Therefore, the evaluation should examine its technical team, quality control system, and response speed.

In addition, the supplier’s inventory capacity and on-time delivery rate are equally critical. This is because the maintenance window for kilns is often extremely tight.

Choosing a reputable refractory brick supplier with a comprehensive service network is essential to ensuring the continuity and economy of steel production.

Henan Ruitai Lianxin Refractory Materials Co., Ltd. has 20 years of experience in refractory material production. It can not only provide customers with high-quality refractory bricks that meet the required standards, but also provide the most suitable kiln operating conditions solutions.

Please feel free to contact us if you have any needs. Choosing Ruitai Lianxin means choosing strength.