Zirconia Mullite Fire Brick

Features of Zirconia mullite fire brick

Application of Zirconia mullite brick

• Glass industry: used in the flame space, flow channel, bottom and bottom sublayer of glass kiln, large arch, small furnace inclined arch and tongue arch, etc.

• Metallurgical industry: can be used for lining of steelmaking furnace, refining furnace, etc., and can resist erosion and scouring of molten steel and slag.

• Petrochemical industry: as lining material of cracking furnace, gasification furnace and other equipment, it provides reliable fire-resistant protection in high temperature, high pressure and complex chemical environment.

• Other fields: can also be used for high temperature kilns in ceramic industry, high temperature sintering furnaces in electronics industry and other equipment.

Zirconia Mullite Brick

| ZM-20 | ZM-16 | ZM-12 | |

| ZrO2(%) | ≥20 | ≥16 | ≥12 |

| SiO2(%) | / | / | / |

| Fe2O3(%) | ≤0.3 | ≤0.3 | ≤0.3 |

| Apparent porosity (%) | ≤13 | ≤13 | ≤14 |

| Bulk density (g/cm3) | ≥3.00 | ≥2.90 | ≥2.95 |

| Cold crushing strength (MPa) | ≥100 | ≥100 | ≥100 |

| Refractoriness under load 0.6% (0.2Mpa) | ≥1700 | ≥1700 | ≥1700 |

What is the Price of Zirconia Mullite Refractory Brick?

The main factors affecting the price include: quantity and type. Zirconia mullite fire bricks are key components for building kilns. Lianxin team will provide different pricing plans according to the different needs of customers. The price of Zirconia mullite fire bricks varies depending on the quantity and model selected. Customers who order large quantities of the same model can enjoy greater discounts.

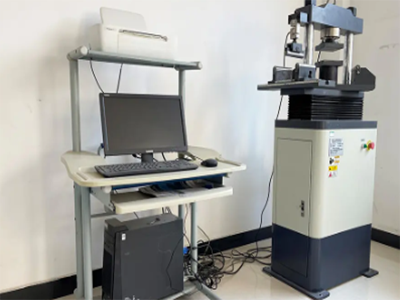

Manufacturing Process of Lianxin Refractory Brick

About Lianxin

The company has more than 20 patented technologies, more than 20 corporate honors, and international certifications such as ISO. With an annual output of 300,000 tons, the company is a leader in China’s refractory industry.

As a refractory materials manufacturer, we will provide you with factory direct prices. With more than 20 years of experience and a team of more than 200 professionals, we are committed to helping you find a solution that suits your needs.

Why choose us?

• Free consultation and free quotes

• High quality at factory prices

• Professional kiln design solutions

• Professional kiln construction experience and technical guidance

• Fast delivery and after-sales service

Customer Cases of Lianxin

Cooperation Partners

.jpg)