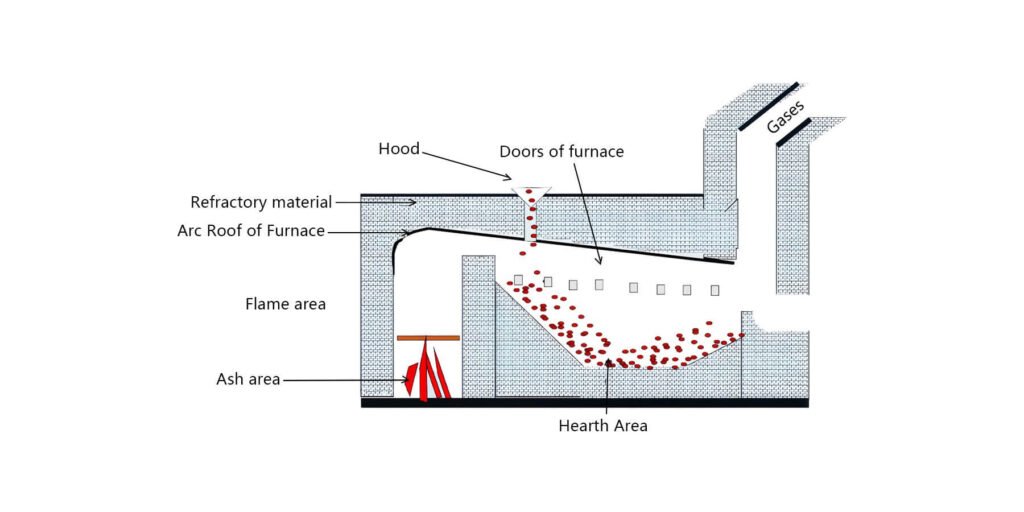

Reverberatory Furnace

Structural Components

A reverberatory furnace is a chamber-type flame furnace widely used in industrial smelting.

Reverberatory furnace consists of a furnace base, furnace bottom, furnace walls, furnace roof, charging port, product discharge port, and flue. Ancillary equipment includes charging devices, air blasting devices, fume exhaust devices, and waste heat recovery devices.

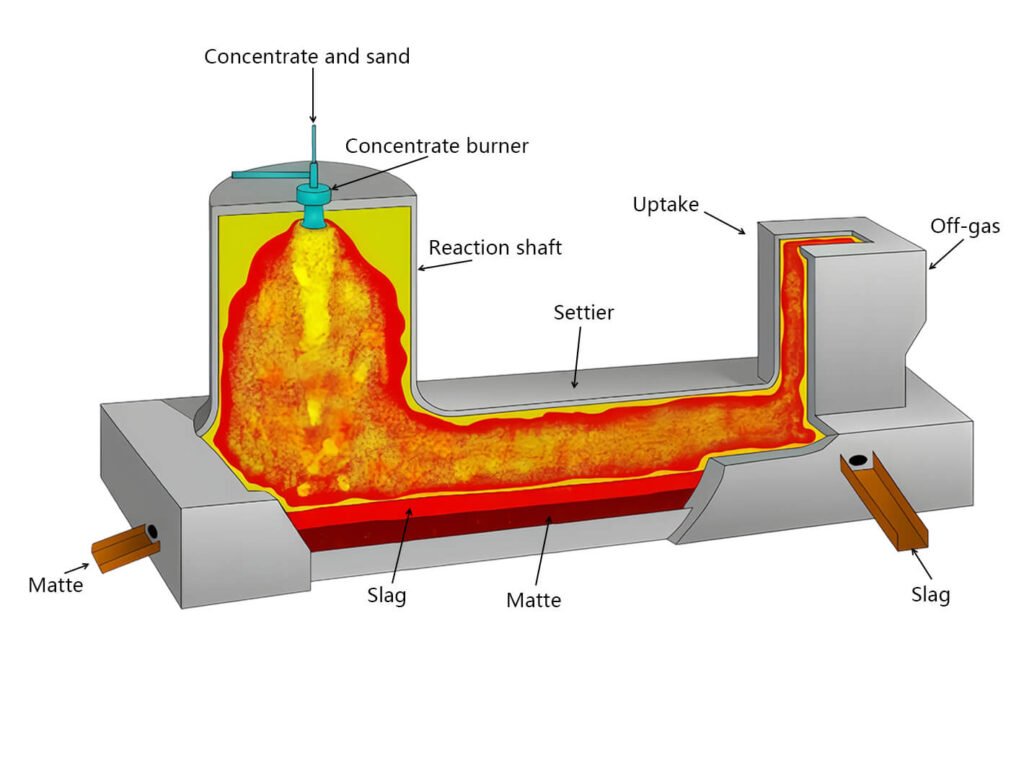

In non-ferrous metal smelting, such as the smelting and refining of copper, lead, zinc and other metals;

In the glass industry, reverberatory furnaces are used to melt glass raw materials to make them into uniform glass liquid.

Operating Principle

Fuel is thoroughly mixed with air and combusted in the combustion chamber, generating high-temperature flames and furnace gases, reaching temperatures of 1500°C to 1700°C or even higher. These high-temperature flames and furnace gases flow within the furnace, transferring some of the heat directly to the material through radiation and some indirectly through reflection from the furnace roof and walls, heating the material, melting it, and initiating physical and chemical reactions.

Furnace Features

- Reverberatory furnace has simple structure, low investment, strong adaptability to raw materials and fuels, capable of processing a wide range of materials, especially fine-grained powders, easy to scale up, and low cost.

- Disadvantages include significant metal oxidation losses, high fuel consumption, large flue gas volumes with low sulfur dioxide concentrations, difficulty in recycling, and environmental pollution.

Furnace Applications

Reverberatory furnaces are important smelting equipment for non-ferrous metals such as copper, nickel, and tin. Reverberatory furnaces are used to process ores and concentrates, smelt ferroalloys, and perform metal fire refining. Reverberatory furnaces are commonly used as roasting equipment in metallurgy and chemical industries.

Refractory Bricks for Reverberatory Furnace

The selection of refractory materials for various parts of a reverberatory furnace is primarily determined by the operating temperature of that area, the properties of the slag it contacts, and the degree of physical erosion it experiences.

Furnace Bottom:

Furnace bottom is typically constructed of magnesia chrome bricks or magnesia carbon bricks.

Furnace Walls:

Magnesia chrome bricks or directly bonded magnesia-chrome bricks are generally used in the critical areas from the furnace bottom to the furnace waist. High alumina bricks are sometimes used in the lower-temperature areas below the furnace roof.

Furnace Roof:

The furnace roof is typically constructed with high-alumina bricks or clay bricks in a vaulted structure. Some large reverberatory furnaces also utilize a suspended furnace roof, employing higher-quality high-alumina bricks or corundum bricks for easier maintenance and replacement.

Flue Duct and Waste Heat Recovery System:

Clay bricks or lightweight clay bricks are generally used, meeting these requirements while effectively reducing costs.