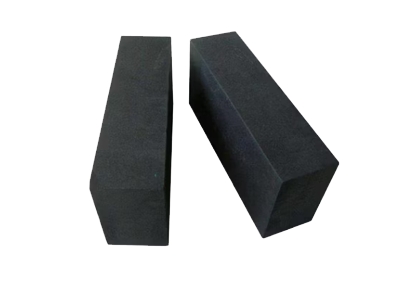

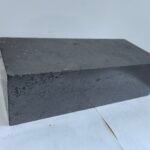

Magnesia Carbon Brick

Features of Magnesia Carbon Fire Brick

Magnesia carbon refractory brick is mainly used for the lining of converters, AC electric arc furnaces, DC electric arc furnaces and the slag line of ladles.

Magnesia Carbon Brick

| MT-10A | MT-14A | MT-14B | MT-18A | MT-18B | |

| Mgo% | ≥80 | ≥76 | ≥74 | ≥72 | ≥70 |

| C% | ≥10 | ≥14 | ≥14 | ≥18 | ≥18 |

| Apparent Porosity(%) | ≤4 | ≤4 | ≤5 | ≤3 | ≤4 |

| Bulk Density(g/cm³) | ≥2.90 | ≥3.00 | ≥2.95 | ≥3.00 | ≥3.00 |

| Cold Crushing Strength(Mpa) | ≥40 | ≥40 | ≥35 | ≥40 | ≥35 |

| High temperature bending strength(1400℃×30min)Mpa | ≥6 | ≥10 | ≥8 | ≥9 | ≥7 |

What is the Price of Magnesia Carbon Bricks?

The main factors influencing price are quantity and model. Magnesia carbon refractory bricks are a key component in kiln construction. The RuitaiLianxin team offers different pricing plans based on customer needs. Magnesia carbon fire brick price depends on the quantity and model selected. Larger orders of the same model offer larger discounts.

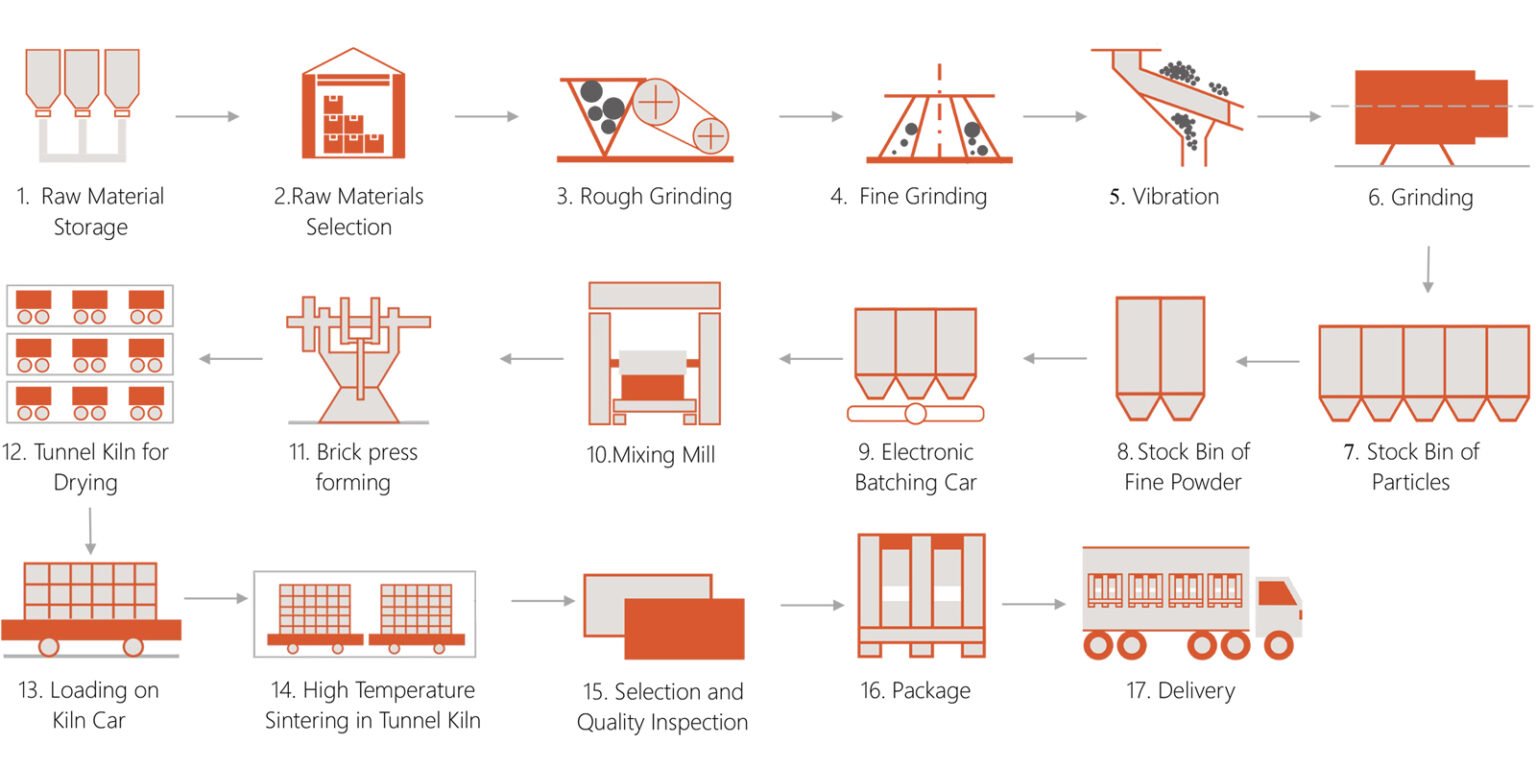

Manufacturing Process of Ruitailianxin Refractory Brick

About Ruitailianxin

The company has more than 20 patented technologies, more than 20 corporate honors, and international certifications such as ISO. With an annual output of 300,000 tons, the company is a leader in China’s refractory industry.

As a refractory bricks manufacturer, we will provide you with factory direct prices. With more than 20 years of experience and a team of more than 200 professionals, we are committed to helping you find a solution that suits your needs.

Why choose us?

• Free consultation and free quotes

• High quality at factory prices

• Professional kiln design solutions

• Professional kiln construction experience and technical guidance

• Fast delivery and after-sales service

Customer Cases

As a world-renowned refractory manufacturer and exporter, our customers come from all over the world, including Kazakhstan, Uzbekistan, India, Russia, etc.The quality of our refractory bricks has won the trust of global customers and gained partners in various industries.

Cooperation Partners

As a refractory fire bricks supplier with source factory, we have many outstanding partners from all walks of life. Together with us, these partners have forged brilliant achievements and injected unlimited impetus into development.

-1024x768.jpg)