Converter

Structural Components

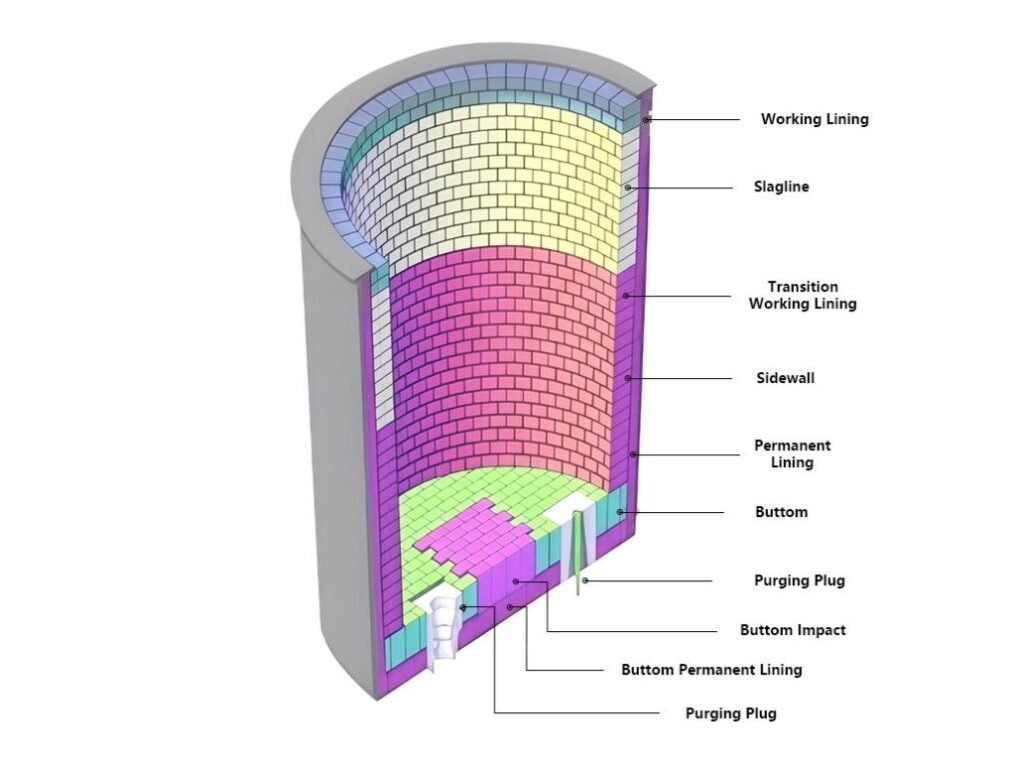

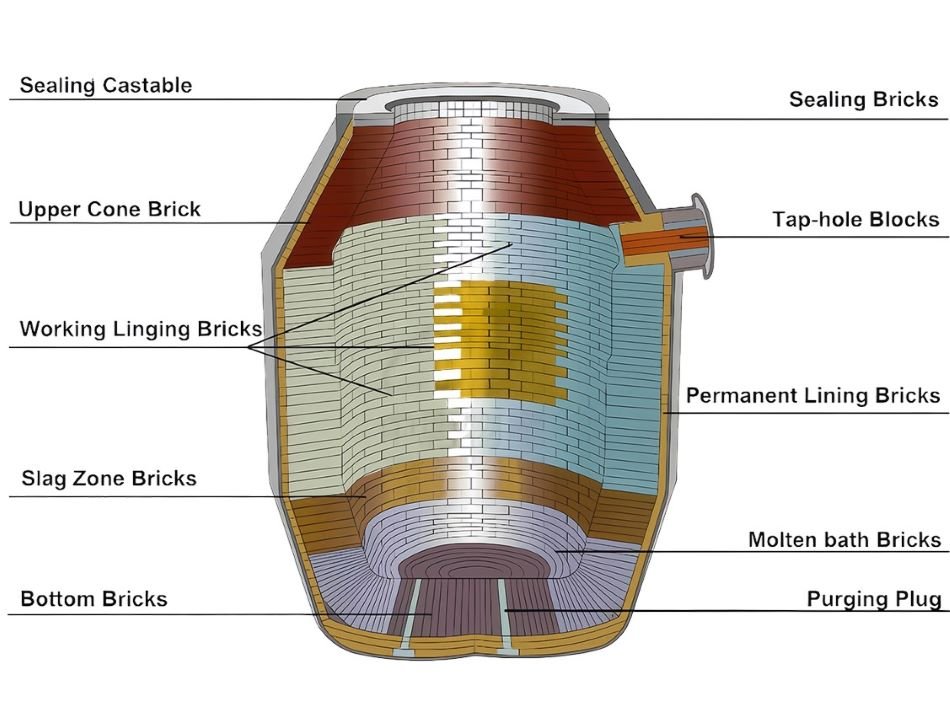

The furnace body consists of a steel plate-welded shell and a refractory lining within it. The lining consists of a working layer, a permanent layer, and a filling layer. The furnace body consists of an upper furnace chamber and a lower furnace bottom.

The furnace cap is often truncated conical in shape to reduce blowing splashes and heat loss, facilitate gas discharge, and is often water-cooled at the furnace mouth. The furnace body, generally cylindrical, serves as the load-bearing part of the furnace. The tapping port is located at the junction of the furnace cap and the refractory bricks of the furnace body.

The support ring supports the entire weight of the furnace body and transmits tilting torque, bearing dynamic loads, impact loads, and thermal loads.

The furnace bottom is available in either truncated-conical or spherical shapes. The truncated-conical shape is used for small and medium-sized converters under 50 tons, while the spherical shape is mostly used for furnaces over 120 tons.

Operating Principle

Take a steelmaking converter as an example: scrap steel and other materials are first loaded into the furnace, followed by molten iron and slag-forming materials. High-pressure oxygen is then blown in through an oxygen lance inserted from the top of the furnace. This oxygen reacts with the hot iron to remove impurities, such as silicon, manganese, and carbon, while generating heat to raise the temperature of the molten steel. When the molten steel reaches the required composition and temperature, blowing is stopped and the furnace body is tilted to tap the steel. Deoxidizers are added during tapping to remove oxygen and adjust the composition.

Furnace Features

1. Outstanding Production Efficiency: Taking the steelmaking converter as an example, a single-furnace smelting cycle is typically only 30-60 minutes, significantly faster than other steelmaking equipment, enabling rapid response to large-scale steel demand.

2. Strong Process Adaptability: It can be used to produce steel using molten iron as the primary raw material, as well as non-ferrous raw materials such as copper matte and nickel matte. Adjustments to the injected gas (such as oxygen or air) and slagging agents can be made to accommodate different smelting objectives.

3. Energy Efficiency and Cost Advantages: The oxidation reaction of the raw materials during the smelting process releases a significant amount of heat, significantly reducing external energy consumption and lowering production costs.

Furnace Applications

Converter is primarily used in steelmaking and is the most important piece of steelmaking equipment. However, converter can also be used in copper and nickel smelting. For example, the horizontal converter can process copper matte, oxidize and convert copper matte into blister copper, and convert nickel matte.

Different parts of the converter are subject to varying degrees of high temperature, slag erosion, and mechanical impact, necessitating significant differences in the refractory materials used. Basic refractories are primarily used in the core (to meet the requirements of steelmaking and slag formation).

Refractory Bricks for Converters

1. Furnace Lining (Core Working Layer)

Furnace Bottom: Magnesia-carbon bricks (ordinary magnesia-carbon bricks, carbon content 10%-14%) are commonly used. More economical fired magnesia bricks can be used in the center of the bottom.

Furnace Shaft (Straight Section): High-grade magnesia-carbon bricks (magnesia purity ≥96%, carbon content 14%-18%) are required for enhanced erosion resistance.

Furnace Cap (Conical Section): Magnesia-carbon bricks or magnesia-alumina-carbon bricks (with added alumina for improved thermal shock resistance) are commonly used to prevent cracking caused by sudden temperature changes.

2. Taphole

Ultra-high erosion-resistant refractory materials are used, primarily alumina-carbon refractories (such as corundum-carbon bricks).

3. Furnace Mouth (Charging/Oxygen Blowing Area)

Mash-in magnesia carbon bricks or precast castable blocks are commonly used (e.g., magnesia castables, which can be cast and repaired on-site and are cost-effective).

4. Permanent Layer and Filling Layer (Non-working Layer)

Permanent Layer: Commonly used are fired magnesia bricks or magnesia-alumina bricks (low cost, high strength, and no direct slag corrosion).

Filling Layer: Generally, bulk magnesia or lightweight magnesia castables are used, which are easy to construct and can absorb the expansion stress of the working layer.