As core equipment in high-temperature industries, the stable operation of kilns relies heavily on high-quality lining materials. Today, we highlight some versatile and cost-effective kiln furnace bricks. In order to help businesses reduce losses and improve production efficiency. It is suitable for kilns in various industries, including steel, glass, cement, and ceramics.

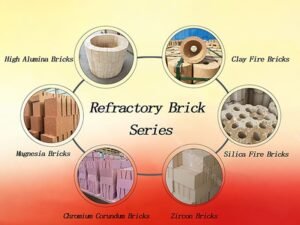

Types of furnace Bricks Used in Kilns

Furnace bricks are classified according to their composition and properties. So the most commonly used types of refractory bricks in kilns include:

Clay Bricks:

These bricks are made from furnaceclay, are economical, and suitable for medium-temperature environments. Then they are typically used in the preheating and cooling zones of kilns.

High-Alumina Bricks:

These bricks have a high alumina content (up to 90%), excellent strength and wear resistance, so making them ideal for the combustion zone of cement kilns.

Silica Bricks:

Primarily composed of silica, these bricks have high thermal shock resistance and are commonly used in glass manufacturing kilns.

Magnesia Bricks:

Made of magnesium oxide, these bricks have strong alkali resistance and are commonly used in steelmaking kilns.

Insulating Bricks:

These lightweight bricks are designed to reduce heat loss and improve energy efficiency. So they are typically used as secondary linings for kilns.

High-quality kiln furnace bricks are a guarantee of efficient and stable industrial production, balancing practicality and economy. Their cost-effectiveness far surpasses that of ordinary furnace materials. Then we sincerely invite all types of high-temperature industrial enterprises to choose Ruitai Lianxin furnace Materials Co., Ltd., to build a solid foundation for production with superior linings.