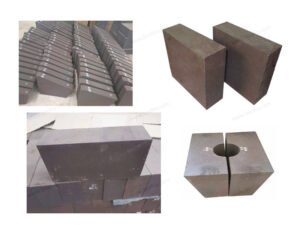

Magnesia refractory fire bricks are alkaline refractory materials made from magnesia (mainly MgO).

Chemical Composition Indicators:

The core indicator is MgO content. Ordinary fired magnesia refractory fire brickshave ≥85% MgO, while high-purity magnesia refractory fire bricks can reach over 95%. Higher content results in stronger resistance to alkaline slag erosion and greater refractoriness.

Physical Performance Indicators:

Bulk density: Fired magnesia refractory fire bricks ≥ 3.0 g/cm³. Higher values indicate a denser structure and stronger resistance to slag penetration.

Apparent porosity: ≤18%. The lower the percentage, the less likely slag will penetrate the brick body.

Room temperature compressive strength: ≥50MPa for fired magnesia refractory bricks, and over 80MPa for high-strength magnesia bricks.

Thermal shock resistance: Measured by the number of water-cooling cycles at 1100℃, ordinary magnesia refractory bricks ≤10 cycles, while magnesia-carbon refractory fire bricks, due to the addition of graphite, exceed 20 cycles.

High-temperature performance indicators

Refractory resistance: ≥1900℃ for ordinary magnesia bricks, and ≥2000℃ for high-purity magnesia bricks.

Load softening temperature (T₀.6): ≥1550℃ when deformation reaches 0.6% under 0.2MPa pressure. The higher the MgO content, the higher the value.

Resistance to alkaline slag erosion: Measured by weight loss rate and erosion depth, this is a core advantage of magnesia refractory bricks, performing significantly better than acid and neutral refractory bricks in alkaline slag environments.

Applications

In the metallurgical industry, magnesia refractory fire bricks are used in high-temperature sections of steelmaking converters, electric arc furnaces, ladles, refining furnaces, and non-ferrous metallurgical furnaces such as copper and nickel furnaces.

In the building materials industry, they are mainly used in the firing zone of cement rotary kilns.

Other high-temperature industries use them in some glass kiln regenerators and high-temperature sections of waste incinerators.