Kiln linings are the safety barrier for high-temperature production, and the design of fire bricks directly determines the kiln’s lifespan and operating efficiency.

Henan Ruitai Lianxin Refractory Materials Co., Ltd., leveraging its extensive industry experience, provides comprehensive solutions from material selection to structural design for different industrial kilns. These solutions include core products such as high-alumina bricks, magnesia-alumina spinel bricks, and silica-mullite bricks.

Material Selection: Adaptability to Operating Conditions is Key

1.1 Selection Based on Temperature and Medium

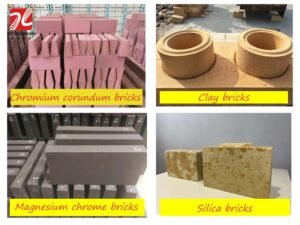

For firing zones above 1600℃, corundum bricks or magnesia bricks are preferred due to their stronger resistance to slag erosion. Magnesia-alumina spinel bricks are suitable for alkaline environments, while silica bricks are more appropriate for acidic conditions.

1.2 Optimization Based on Industry Scenarios

High-alumina bricks with anti-spassing properties are used in the preheating zone of cement rotary kilns, while magnesia-carbon bricks are used in the slag line zone of steel converters. Henan Ruitai Lianxin can customize exclusive material combination solutions according to kiln type.

Structural Design: Balancing Stability and Energy Efficiency

2.1 Masonry Structure Design

A staggered masonry technique is employed to enhance the overall integrity of the lining. Mortar joints in high-temperature zones are controlled within 1mm and filled with specialized ultrafine refractory mortar. A 5-6mm expansion joint is reserved per meter to prevent thermal expansion cracking.

2.2 Composite Insulation Design

A composite structure of “working layer + insulation layer” is adopted. The working layer uses dense refractory bricks, while the insulation layer is combined with lightweight high-alumina bricks or ceramic fibers. This reduces heat loss and lowers the temperature of the kiln shell.

Detail Control: Mitigating Failure Risks

3.1 Brick Shape and Size Matching

Irregularly shaped bricks are used in complex areas, with dimensional deviations controlled within ±2mm. Precast blocks are preferred for large kilns to reduce on-site cutting waste and improve construction efficiency.

3.2 Reinforced Design for Special Areas

Silicon carbide composite bricks are used to enhance wear resistance in high-wear areas such as kiln openings and elbows. The furnace roof employs a suspended brick structure to ensure mechanical stability at high temperatures.

Henan Ruitai Lianxin, with its high-quality fire bricks and professional design capabilities, has served multiple industries including cement, steel, and glass.

The company provides a one-stop service including material testing, structural simulation, and construction guidance. Its core products—high-alumina bricks, magnesia-alumina spinel bricks, and silica-mullite bricks—have all undergone strict quality control.

If you have needs for kiln lining design or refractory brick selection, please contact us! We will tailor solutions to help your kiln operate efficiently and stably.