The ladle is a crucial piece of equipment in metallurgical production, used for holding and transferring molten steel. The quality of the fire bricks used in the lining directly affects the ladle’s service life. The purity of the molten steel, and production safety.

Henan Ruitai Lianxin Refractory Materials Co., Ltd. has been deeply involved in the refractory materials field for many years. With its high-quality products and customized services, it has become a core supplier of refractory bricks for ladle linings.

Working Conditions of Ladle Linings and Core Requirements for Refractory Bricks

The ladle lining must withstand temperatures above 1600℃, molten steel erosion, slag corrosion, and alternating hot and cold shocks, making the working conditions extremely harsh.

Therefore, the fire bricks used for linings must meet three core requirements: excellent high-temperature resistance, strong erosion resistance, and good thermal shock stability. They must also be compatible with the stress characteristics of different parts of the ladle.

1. Working Layer: The “Protective Core” Directly Facing Molten Steel

The working layer, which comes into direct contact with molten steel and slag, is a critical component of the furnace lining. Therefore, high-strength, highly corrosion-resistant refractory bricks are required to resist the erosion and chemical corrosion of the molten steel, thereby ensuring the quality of the molten steel.

2. Permanent Layer and Insulation Layer: Key to Safety and Energy Saving

The permanent supporting layer must possess good structural stability. The insulation layer is tightly attached to the steel ladle shell, and its main functions are to reduce heat loss, protect the shell from high-temperature damage, and reduce energy consumption.

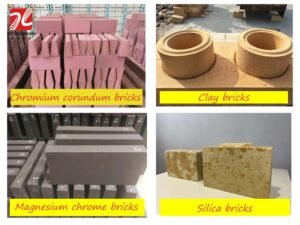

Mainstream Types and Selection Recommendations for Ladle Lining Refractory Bricks

1. Preferred Working Layer: High-Alumina Bricks and Magnesia-Carbon Bricks

High-alumina fire bricks (alumina content ≥65%) produced by Henan Ruitai Lianxin are made from high-quality bauxite clinker, resistant to high temperatures and acidic slag corrosion, suitable for small and medium-capacity ladles and ordinary carbon steel smelting.

Magnesia-carbon bricks, made from fused magnesia and graphite, have outstanding resistance to alkaline slag, making them an ideal choice for large-capacity ladles and special steel smelting.

2. Permanent Layer Compatibility: Clay Fire Bricks

Clay fire bricks offer high cost-effectiveness, possessing excellent mechanical strength and thermal insulation properties. They effectively support the working layer, reducing the overall cost of the lining and making them the mainstream product for the permanent layer of steel ladles.

3. Preferred Insulation Layer: Lightweight Insulating Refractory Bricks

Lightweight insulating refractory bricks have low bulk density and low thermal conductivity. Furthermore, they can significantly reduce heat transfer, lighten the weight of the ladle. And improve heat transfer efficiency, thus meeting the requirements of the ladle insulation layer.

Core Advantages of Henan Ruitai Lianxin Refractory Bricks

1. Strong Customized Production Capability

Therefore, we can tailor-make refractory bricks for ladle linings based on ladle capacity, type of steel being smelted, and operating conditions, precisely meeting the specific needs of our customers.

We also customize refractory bricks of different materials and specifications to precisely match production requirements.

2. Strict Quality Control

From raw material procurement to finished product delivery, we conduct multiple tests throughout the entire process. This ensures that the various indicators of high-alumina bricks, magnesia-carbon bricks, and corundum refractory bricks meet the standards and that their performance is stable.

3. Full-Process Technical Support

We provide one-stop services including lining construction guidance and product usage tracking. We also help customers optimize ladle operation processes and extend service life.

If you have any needs for purchasing refractory bricks for ladle linings, seeking selection consultation, or require customized refractory material solutions, please feel free to contact us!