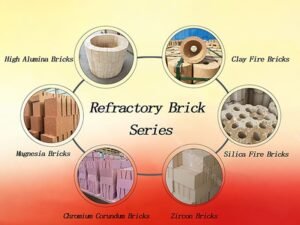

The high-temperature smelting process in the metallurgical industry relies heavily on the reliable protection provided by refractory fire bricks. As a key material for resisting high temperatures, erosion, and wear, different types of refractory fire bricks play an irreplaceable role in ironmaking, steelmaking, and non-ferrous metal smelting.

Selecting the right refractory fire bricks can significantly extend equipment life and reduce production costs.

Ironmaking Process: The Fundamental Protective Role of Refractory Fire Bricks

Core Suitable Brick Types for Blast Furnace Linings

The blast furnace is the core equipment in ironmaking. And the requirements for refractory fire bricks vary significantly depending on the location within the furnace. The hearth and bottom areas have extremely high temperatures, requiring carbon bricks with excellent slag resistance and thermal conductivity to effectively resist the erosion of molten iron and slag.

High-alumina bricks are commonly used in the lower and middle parts of the furnace, balancing high-temperature resistance and wear resistance. For the upper part of the furnace, where temperatures are relatively lower, clay bricks, offering better cost-effectiveness, become the ideal choice.

Steelmaking Process: Precise Adaptation to Different Smelting Equipment

Dedicated Refractory Fire Brick Solutions for Converters and Electric Furnaces

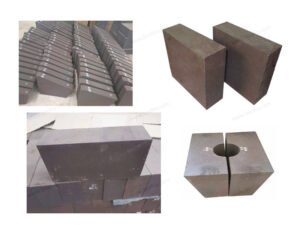

During converter smelting, the furnace lining must withstand drastic temperature fluctuations and slag erosion. Magnesia-carbon bricks, with their excellent high-temperature strength and resistance to alkaline slag erosion, are the preferred choice for converter linings.

Electric furnace smelting conditions are more complex. Corundum bricks are commonly used for the furnace roof and walls. That as their high purity resists the chemical corrosion of molten steel. Furthermore, the ladle, as a steel transfer device, is often lined with alumina-magnesia-carbon bricks, providing both insulation and corrosion resistance.

Details of Refractory Fire Brick Application in Continuous Casting

In continuous casting, the tundish is crucial for steel purification and diversion. Basic refractory fire bricks are commonly used for tundish lining to effectively reduce secondary contamination of the molten steel. High-performance zirconium-corundum bricks are required for critical components such as nozzles and stoppers to ensure smooth steel flow and prevent blockages.

Non-ferrous Metal Smelting: Coping with Corrosion from Special Media

Non-ferrous metal smelting often faces corrosion from acidic or alkaline slags, placing higher demands on the corrosion resistance of refractory fire bricks. When smelting metals such as copper, lead, and zinc, magnesia-chrome bricks or chrome corundum bricks are commonly used. As they can resist the strong corrosion of non-ferrous metal slags.

In aluminum electrolysis cells, silicon carbide bricks, due to their excellent thermal conductivity and erosion resistance, have become the core material for the lining.

The selection of refractory bricks in the metallurgical field must consider key factors such as equipment operating conditions, smelting media, and temperature. Selecting the right high-quality refractory fire bricks is crucial for ensuring stable production and improving efficiency.

For many years, we have been deeply involved in the field of refractory materials. And can provide a full range of metallurgical refractory bricks, including carbon bricks, magnesia-carbon bricks, and corundum bricks. We also have a professional team to customize exclusive selection solutions for you.

Whether you have refractory needs for blast furnaces, converters, or non-ferrous metal smelting equipment, please contact us for one-on-one technical support and cost-effective product quotes!