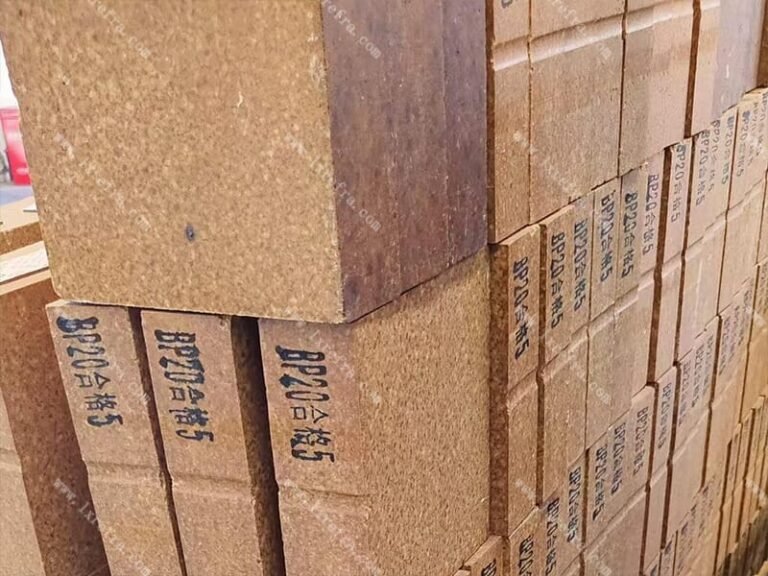

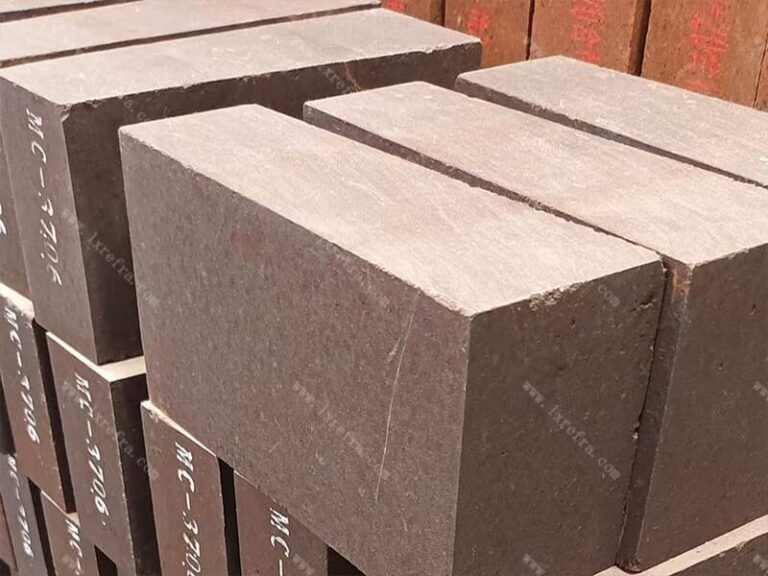

High-Quality Refractory Fire Brick Suppliers

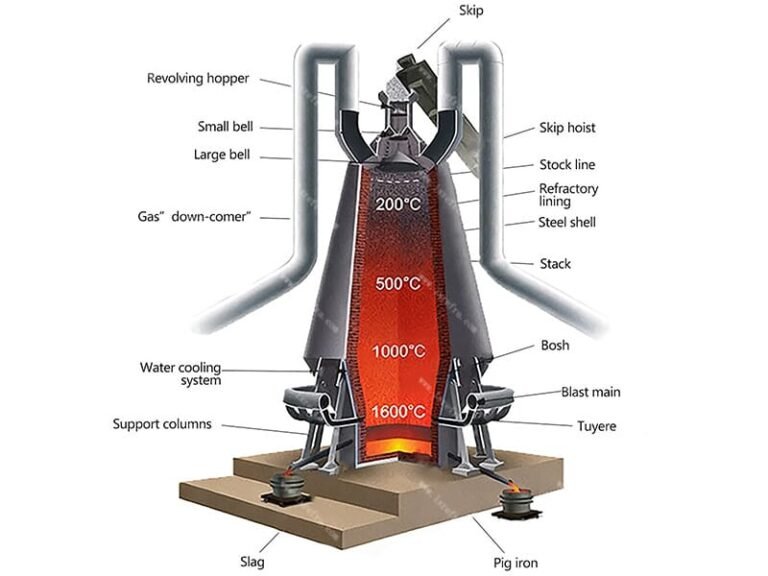

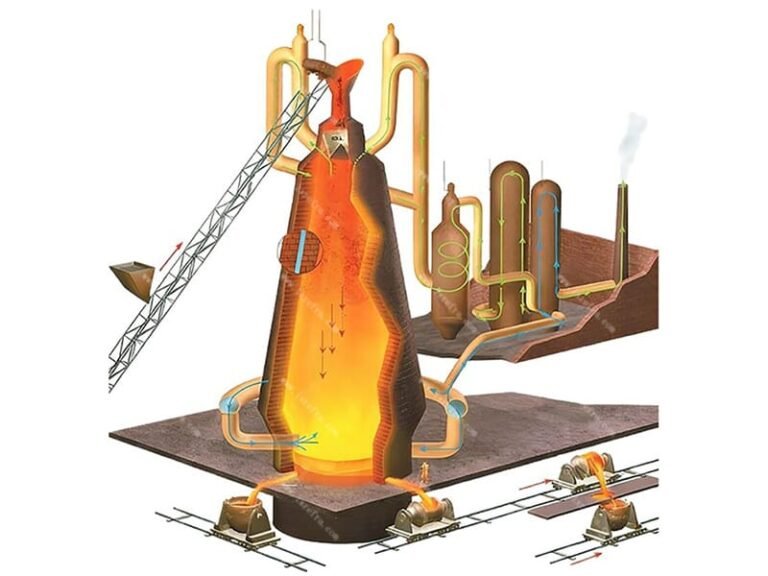

In high-temperature industries such as steel, cement, and glass, refractory fire bricks are core materials for withstanding temperatures exceeding 1000 degrees Celsius and ensuring stable production. High-quality suppliers are crucial partners for enterprises in building a robust “safety defense line.”…