Industrial kilns face severe challenges from high-temperature molten slag and corrosive gases. The anti-corrosion performance of fire bricks directly determines the operating efficiency of the equipment.

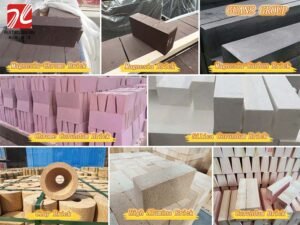

Henan Ruitai Lianxin Refractory Materials Co., Ltd. is deeply committed to technological research and development. By optimizing material formulations and production processes, it has launched anti-corrosion products such as magnesia-carbon bricks, magnesia-alumina spinel bricks, and corundum bricks, suitable for high-temperature conditions in various industries.

Core Principles of Anti-corrosion Technology

1.1 Material Composition Optimization

High-purity alumina and magnesium oxide are typically selected as the main raw materials, while the content of impurities such as silicon and iron is strictly controlled.

1.2 Structural Densification Process

High-temperature sintering and vacuum pressing techniques are typically used to reduce the porosity of the bricks. This creates a fine and uniform pore structure, blocks the penetration channels of molten slag, slows the diffusion of corrosive media into the interior, and enhances the corrosion resistance of the bricks.

Anti-corrosion Selection Schemes for Different Operating Conditions

2.1 Alkaline Slag Conditions

In steel smelting converters, electric furnaces, and other similar applications, magnesia-carbon bricks and magnesia-alumina spinel bricks are generally preferred.

These alkaline fire bricks are acid-base compatible with steel slag, resisting corrosion from Fe₂O₃, CaO, and other components, significantly extending the service life of the slag line area.

2.2 Acidic/Complex Corrosion Conditions

For glass kilns, chemical reactors, and similar applications, corundum bricks and high-alumina bricks are suitable. These products are rich in Al₂O₃, exhibiting strong chemical stability and resisting the dual corrosion of acidic slag and corrosive gases, ensuring the integrity of the lining.

Henan Ruitai Lianxin’s Technical Advantages

3.1 Customized R&D Capabilities

For different industry kiln operating conditions, we precisely match the acid-base and density parameters of fire bricks. We can provide customers with customized anti-corrosion solutions to solve corrosion problems under special operating conditions.

3.2 Quality Control System

Core products have passed high-temperature erosion simulation tests, achieving advanced corrosion resistance levels in the industry.

Henan Ruitai Lianxin provides reliable fire bricks to the steel, cement, and glass industries, leveraging its professional anti-erosion technology. Our product range covers core categories such as magnesia-carbon bricks, corundum bricks, and magnesia-alumina spinel bricks.

If you have any needs for refractory brick selection, anti-erosion technology consultation, or procurement, please contact us! Our professional team will tailor a solution for you, using high-quality anti-erosion refractory bricks to strengthen your production defenses and help your company reduce costs and increase efficiency.